High speed forming

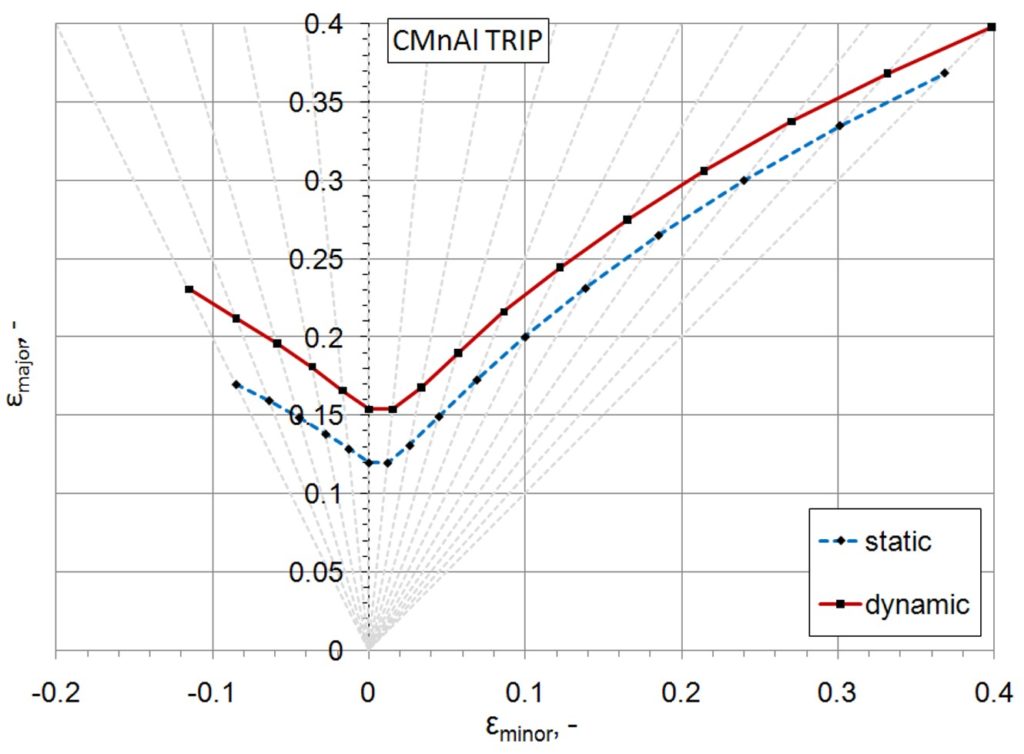

The strain rate dependence of plastic yield and failure properties displayed by most metals affects energies,

forces and forming limits involved in high speed forming processes. At DyMaLab, the influence of the strain rate on the forming properties of several sheet metals isstudied. An approach was developed to predict dynamic forming limit diagrams (FLDs) based on dynamic tensile tests using the Marciniak–Kuczynski method. Recently a more fundamental methodology is developed combining test results of the new, purpose-developed, dynamic bulge test setup with advanced plasticity modeling.

Key Publications