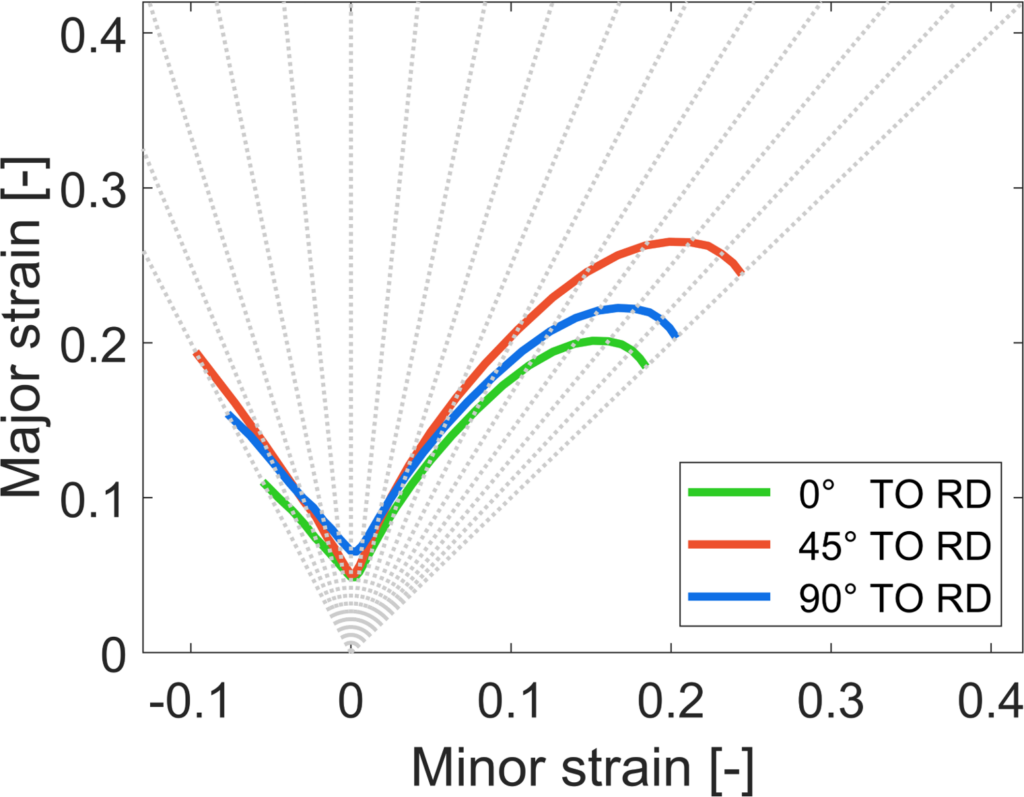

Forming limit diagram prediction

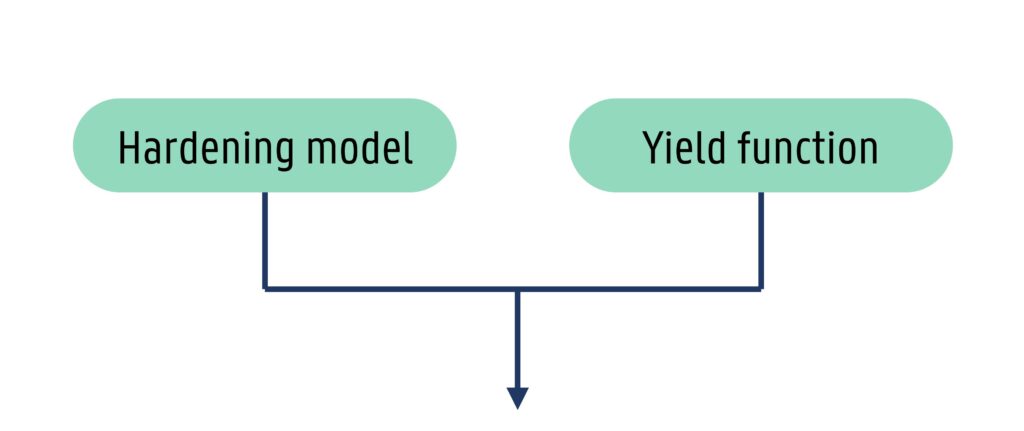

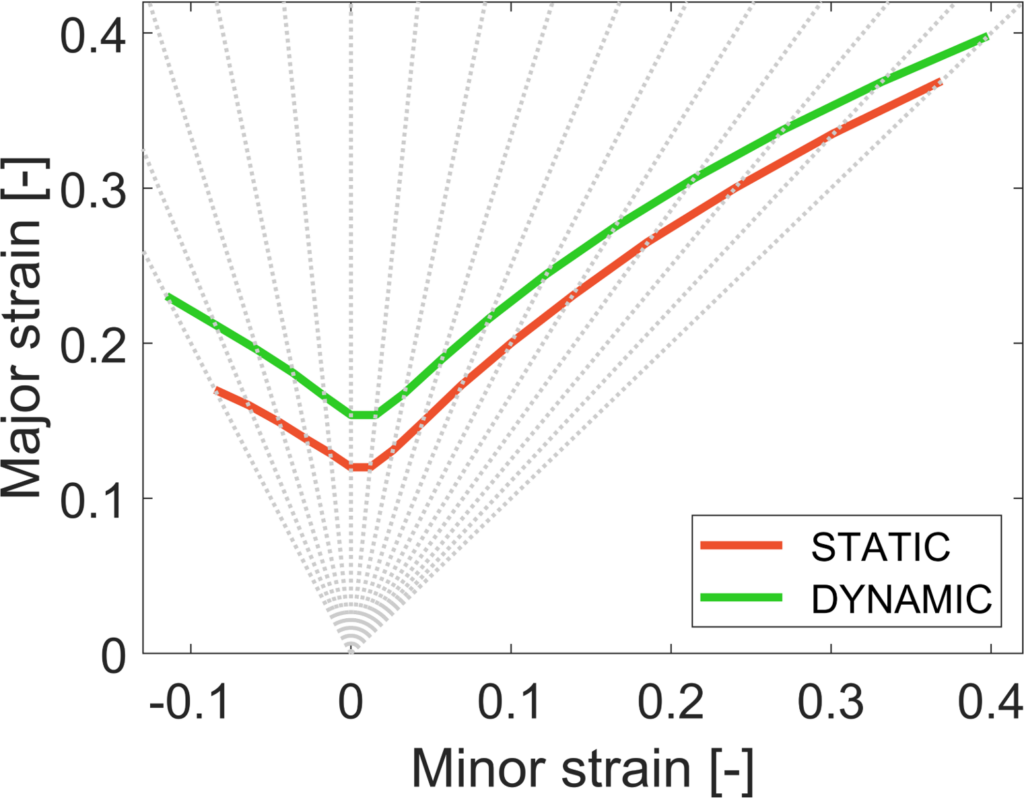

To assess the formability of a sheet metal, Forming Limit Diagrams (FLDs) are widely used. Within DyMaForm, a numerical tool, able to build the FLD based on the Marciniak-Kuczynski technique, is developed. The input needed for the FLD Tool is the materials plasticity model, consisting of a yield function and a hardening law.

The outcome of the FLD Tool is provided quasi-instantaneously. This facilitates fast screening of the deformation capacity of materials and allows us to provide a fast answer to industrial forming questions.

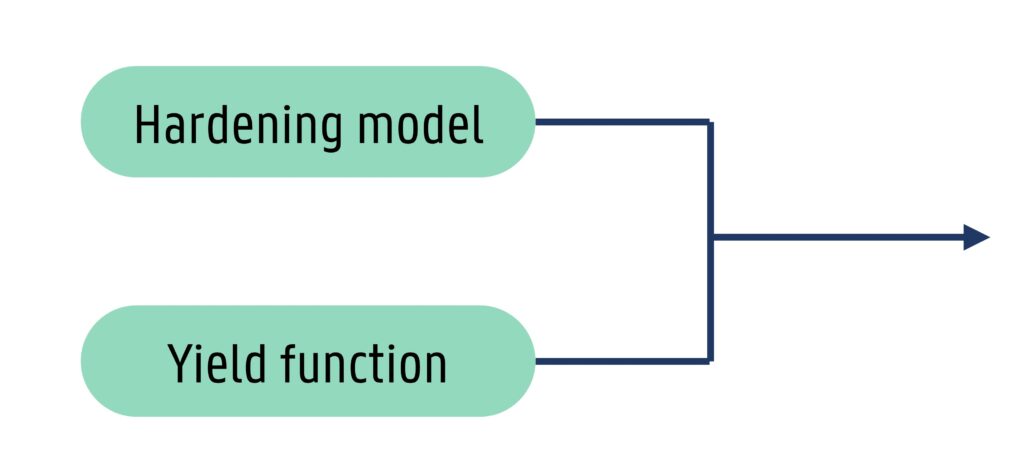

Hardening models

- Swift

- Voce

- Combined Swift-Voce

- Johnson-Cook

Yield functions

- von Mises

- Hill48

Hardening models

- Swift

- Voce

- Combined Swift-Voce

- Johnson-Cook

Yield functions

- von Mises

- Hill48

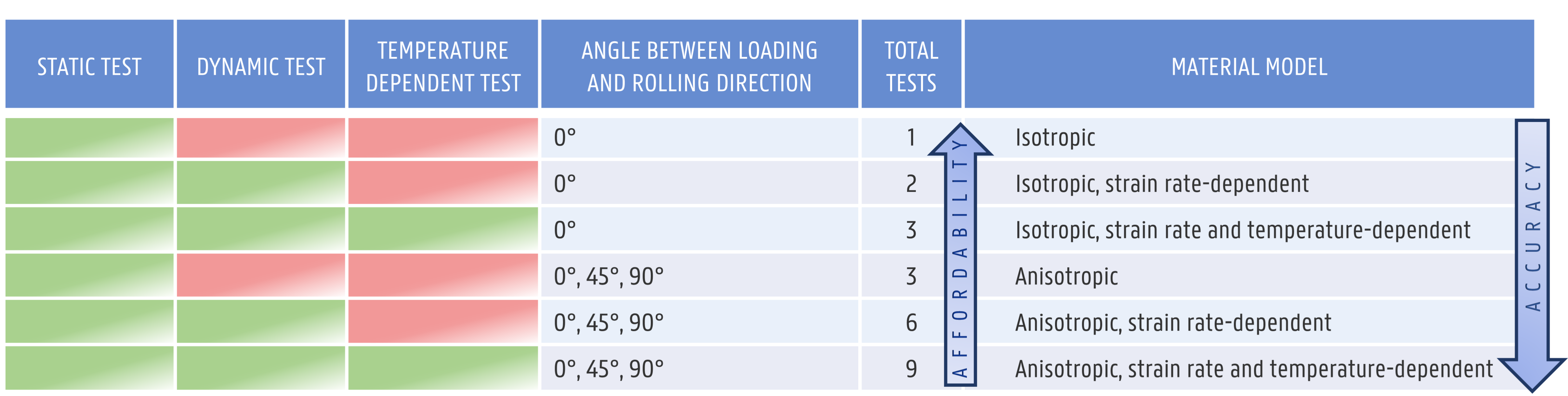

Obviously, the predictive capability of the FLD Tool depends on the used plasticity model. In this regard, the developed FLD tool is extremely flexible. Indeed, it allows generating FLDs through models calibrated by only one test to models based on comprehensive datasets, including tests along different directions, at different temperatures and/or deformation rates. If the former enables a fast approximate assessment of the feasibility of a specific forming process, the latter allows a more in-depth assessment of complex forming operations.

Key publications

- Verleysen, P., Peirs, J., Van Slycken, J., Faes, K., & Duchene, L. (2011). Effect of strain rate on the forming behaviour of sheet metals. Journal of Materials Processing Technology, 211(8), 1457–1464.

- Verleysen, P., Galan-Lopez, J. (2016). Experimental and numerical prediction of the static and dynamic forming properties of Ti6Al4V. In International conference on High Speed Forming 2016. Dortmund.

- Lonardi, C., Corallo, L., & Verleysen, P. (2022). Prediction of Forming Limit Diagram Using the Marciniak-Kuczynski Method for Ti-6Al-4V Using Different Material Models. Key Engineering Materials, 926, 885–896.