Static and dynamic bulge testing

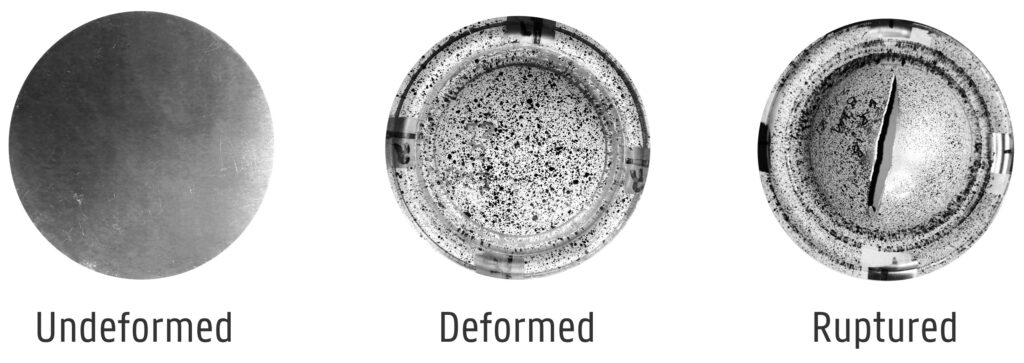

Static and dynamic bulge test facilities are available, allowing the characterisation of sheet metals under quasi-biaxial tension. Bulge tests are highly valuable for forming, because both high deformations are achieved and the deformation mode is very relevant for deep drawing processes. Together with the already available static and dynamic methodologies for tensile, compression, torsion, in-plane shear and plane strain testing, the bulge setups enable a full identification of the formability of sheet metals. Moreover, the outcome allows the validation of the FLD Tool.

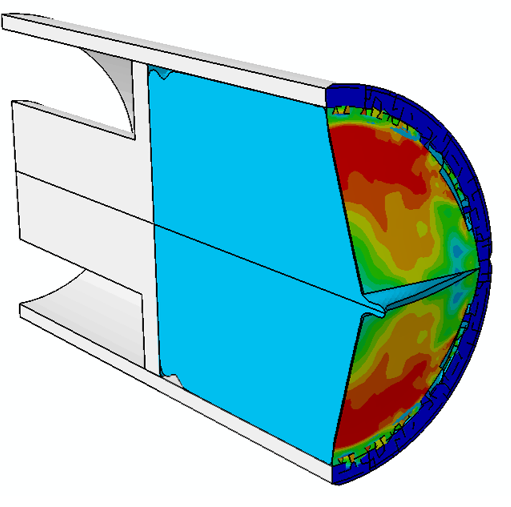

During a bulge test, a circular metal sheet sample is subjected to a hydrostatic pressure by a liquid. In the dynamic setup, the liquid is pressurised by a piston moving at a high and adjustable speed, resulting in high strain rates in the sample. The deformation of the sample is monitored by static or high speed cameras. The dynamic bulge test setup was developed in-house and combines basic features of split Hopkinson compression bar and static bulge tests.