Dynamic behaviour of polymers

Epoxy resins are characterized by a good combination of mechanical properties, such as high stiffness and excellent fatigue performance. Besides that, they are typically designed for resin transfer molding (RTF) applications, which offer a low-cost alternative to conventional production processes for several aircraft components. However, aircraft structures might be subjected to impact loads, such as bird and hail strikes. Therefore, it is important to understand the behaviour of epoxy resins at high strain rates.

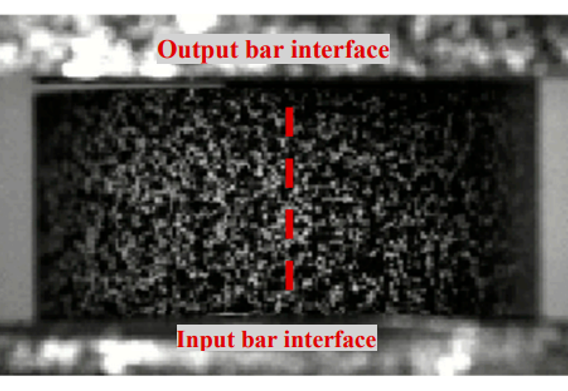

DyMaLab is currently involved in studies on the strain rate effect on the compressive behaviour of epoxy resins. This is particularly relevant because of the lack of proper data on this material. Indeed, dynamic testing of epoxy is not straightforward because of the challenges related to the aspects listed below:

- Design of an appropriate sample geometry

- Boundary conditions at the loading interfaces

- Assumptions related to the material itself

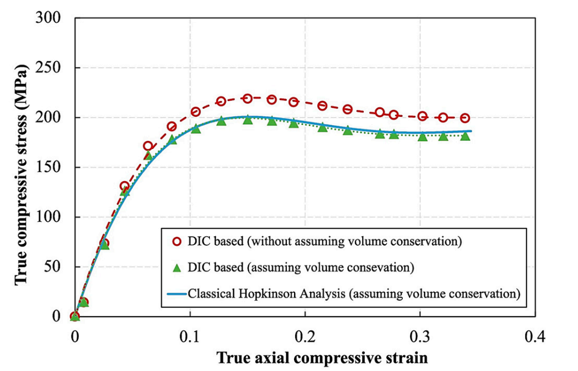

Recent studies performed at DyMaLab showed that these challenges can be overcome. New insights on epoxies were obtained:

- Epoxy resin is highly strain rate sensitive in compression.

- The peak yield strength and the barreling ratio show an increase and a decrease, respectively, with the increasing strain rate.

- The commonly made assumption of volume conservation in the yielding stage is not valid.