Dynamic behaviour of titanium alloy

Ti-6Al-4V is the most used titanium alloy, due to the excellent combination of low weight, good mechanical properties and resistance to severe service conditions. Both in its applications (aircraft components, turbine blades, sports equipment, …) and during its production processes (machining, punching, deep drawing, incremental forming, cutting, …), Ti-6Al-4V is often subjected to dynamic loads. Therefore, for an optimal production and use of titanium it is crucial to understand its behaviour at high strain rates.

During over a decade, DyMaLab has extensively investigated the Ti-6Al-4V behaviour under dynamic conditions by means of:

- Extensive test campaigns, characterized by different strain rate levels and loading modes (tensile, compression, in-plane shear, torsion, plane strain).

- Experimental and numerical investigation of the high strain rate effect on the anisotropic response of the material.

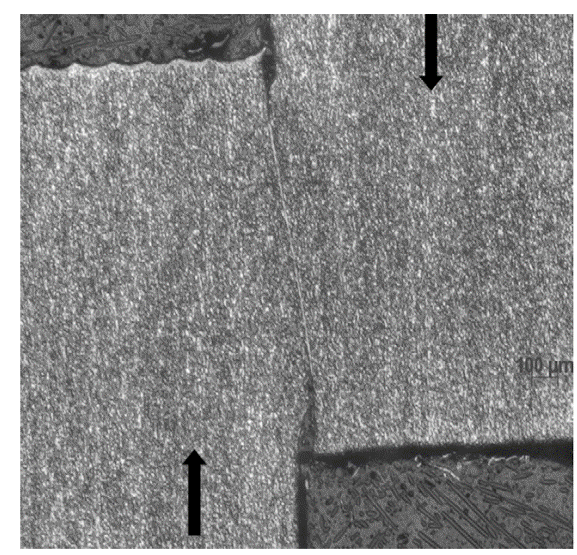

- Analysis of the microstructural deformation evolution of shear bands by means of interrupted tests.

- Dynamic bulge experiments with an in-house developed setup, enabling to characterize the plastic behaviour until high levels of plastic strain.

Key publications

- Verleysen, P., Peirs, J. (2017). Quasi-static and high strain rate fracture behaviour of Ti6Al4V. International Journal of Impact Engineering, 108, 370–388.

- Peirs, J., Tirry, W., Amin-Ahmadi, B., Coghe, F., Verleysen, P., Rabet, L., Schryvers, D., & Degrieck, J. (2013). Microstructure of adiabatic shear bands in Ti6Al4V. Materials Characterization, 75, 79–92.

- Peirs, J., Verleysen, P., Degrieck, J., & Coghe, F. (2010). The use of hat-shaped specimens to study the high strain rate shear behaviour of Ti–6Al–4V. International Journal of Impact Engineering, 37(6), 703–714.