Dynamic Damage Testing

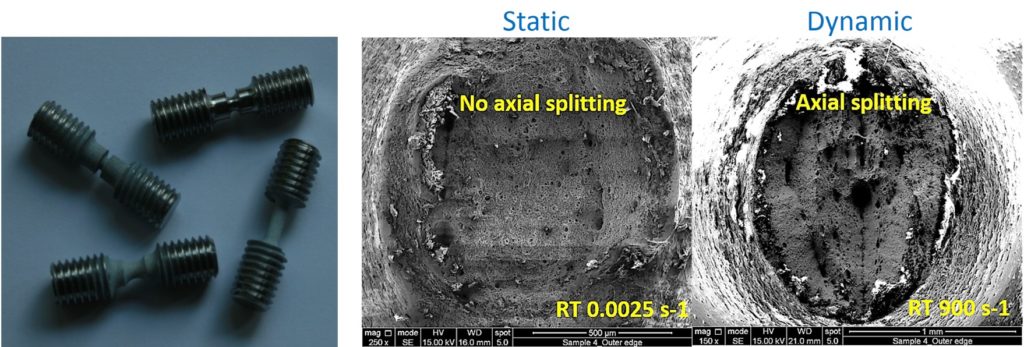

To characterize dynamic damage and fracture properties of materials, at DyMaLab multiple sample geometries and loading configurations have been developed. Aiming at high stress triaxialities, notched samples loaded at high strain rate in the split Hopkinson tensile bar are used. For negative stress triaxialities, dynamic compression of constrained samples or combined torsion/compression are performed. Low triaxialities are reached in well-designed shear samples or torsion samples.

Additionally, setups are available for dynamic fracture characterization using single edge notched tension (SENT) and bending (SENB) samples.

Key Publications

- https://biblio.ugent.be/publication/8577781

- M. Calle, P. Verleysen, M. Alves (2017): Benchmark study of failure criteria for ship collision modeling using purpose-designed tensile specimen geometries. Marine Structures 53 68-85 DOI: 10.1016/j.marstruc.2017.01.001-

- Chandran, S; Verleysen, P; Lian, J; et al. (2017): Design of an experimental program to assess the dynamic fracture properties of a dual phase automotive steel. DYMAT International Conference on Dynamic Fracture of Ductile Materials. Procedia Engineering 197 204-213

- Chandran S, Verleysen P, Lian J, Liu W, Cooreman S, Münstermann S (2017) Dynamic fracture behavior of high strength pipeline steel. DYMAT International Conference on Dynamic Fracture of Ductile Materials. Procedia Engineering 197 214-223