Dynamic Compression Testing

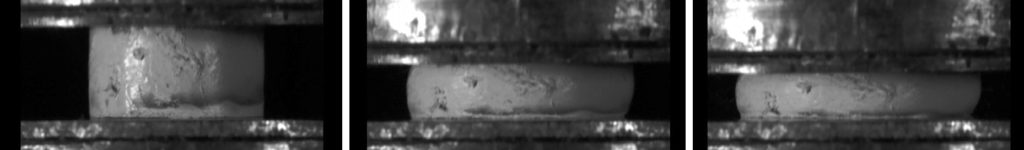

For dynamic compression testing, DyMaLab disposes of a Split Hopkinson Compression Bar (SHCB) setup with a large deformation capacity. SHCB setups are used to study the constitutive, damage and fracture behaviour of materials at strain rates from 100 s-1 up to 10 000 s-1. As is the case for tensile setups, SHCB setups involve a short test sample sandwiched between two long bars: an input bar and an output bar. Acceleration of an impactor towards the free end of the input bar generates the incident compression wave which propagates along the input bar towards the specimen. The velocity of the impactor determines the strain rate in the sample, and can thus be adapted. The incident wave interacts with the specimen, generating a reflected wave and a transmitted wave. The incident, reflected and transmitted waves are measured using strain gauges at well-chosen locations on the Hopkinson bars. From these waves, the total force and deformation history of the specimen can be determined based on the principle of elastic wave propagation in slender bars. However, in order to obtain detailed information on the displacement and strain fields in the specimen, for most tests an additional full-field deformation measurement technique is used.

Technical Specifications

- Total setup length = 12 meter, enabling loading times up to 1.2 ms

- Strain gauge measurements on Hopkinson bars

- Cylindrical or cube sample with dimensions to achieve dynamic equilibrium during high strain rate deformation

- Strain rates from 100 s-1 to 2 000 s-1 and strains exceeding 200% can be achieved

- Local strain measurements using high speed camera imaging and digital image correlation

- Dynamic uniaxial compression testing of advanced high strength steels, pipeline steels, stainless steels, aluminium alloys, titanium alloys, fibre reinforced composites, nanocomposites, …