Dynamic Shear Testing

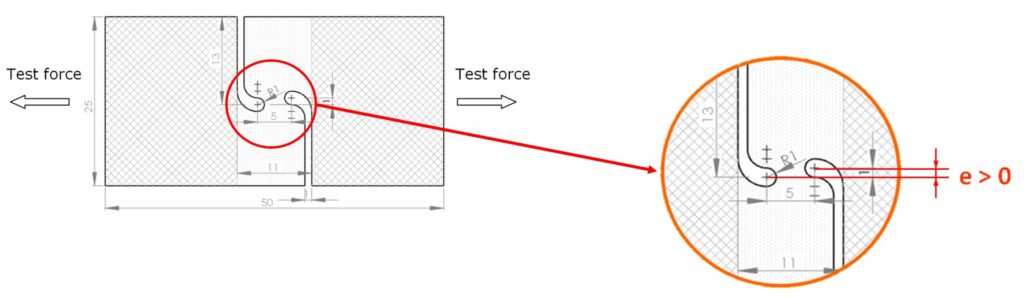

At DyMaLab a novel shear specimen geometry was developed that can be used for static and dynamic tests. The main objectives during the design of the shear specimen were to obtain a homogeneous stress state with low stress triaxiality in the zone of the specimen subjected to shear and to be suited for dynamic testing. Additionally, avoiding premature specimen failure due to edge effects was aimed at.

Technical Specifications

- Strain rates from static to 2 000 s-1 and high strain levels can be achieved

- Full field strain monitoring by high speed digital image correlation

- Parametric finite element model available to optimize the shear sample geometry for a specific material

Key Publications

- Verleysen P., Shear Testing using the Kolsky-Hopkinson Bar Machine, in: The Kolsky-Hopkinson Bar Machine: Selected Topics, Chapter 3, pp. 75-120 (2018)

- Peirs J., Verleysen P. and Degrieck J., Novel Technique for Static and Dynamic Shear Testing of Ti6Al4V Sheet, Experimental Mechanics, vol. 52(7), pp. 729-741 (2012)

- Peirs J., Verleysen P., Van Paepegem W. and Degrieck J., Determining the Stress-Strain Behaviour at Large Strains from High Strain Rate Tensile and Shear Experiments, International Journal of Impact Engineering, vol. 38(5), pp. 406-415 (2011)

- Peirs J., Verleysen P. and Degrieck J., Experimental Study of the High Strain Rate Shear Behaviour of Ti6Al4V, Applied Mechanics and Materials, vol. 82, pp. 130-135 (2011)