Quenching and partitioning advanced high strength steels

The strain rate dependence of plastic yield and failure properties displayed by most metals affects energies, forces and forming limits involved in high speed forming processes. At DyMaLab, the influence of the strain rate on the forming properties of several sheet metals isstudied. An approach was devaBecause of their excellent combination of strength and ductility, quenching and partitioning (Q & P) steels have a great chance of becoming a prominent member of the third generation of advanced high strength steels. The large ductility of Q & P steels arises from the presence of 10% to 15% of retained austenite which postpones necking due to the transformation induced plasticity (TRIP) effect.

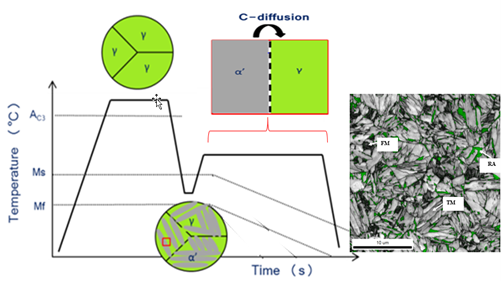

The complex microstructure is obtained via a quench to a temperature situated in between the martensite start and martensite finish temperature, followed by a partitioning step.

At MST, the temperature and strain rate dependent mechanical behavior of several Q & P steels was extensively studied.

Key Publications

- Vercruysse F, Celada-Casero C, Linke B, Verleysen P, Petrov R (2020) Temperature Dependence of the Static and Dynamic Behaviour in a Quenching and Partitioning Processed Low-Si Steel. Metals.